Manufacturing Excellence

At LX CABLE, we pride ourselves on our cutting-edge manufacturing processes, which ensure the highest quality and reliability in every product we create. Our advanced facilities, skilled workforce, and stringent quality control measures are the backbone of our manufacturing excellence.

Advanced Production Facilities

Our manufacturing plant is equipped with the latest machinery and technology to produce a wide range of power transmission products. From cables to connectors and accessories, we have the capability to handle large-scale production while maintaining exceptional quality standards.

Precision Manufacturing

At LX CABLE, we ensure every step of our cable manufacturing process meets the highest standards of quality and efficiency.

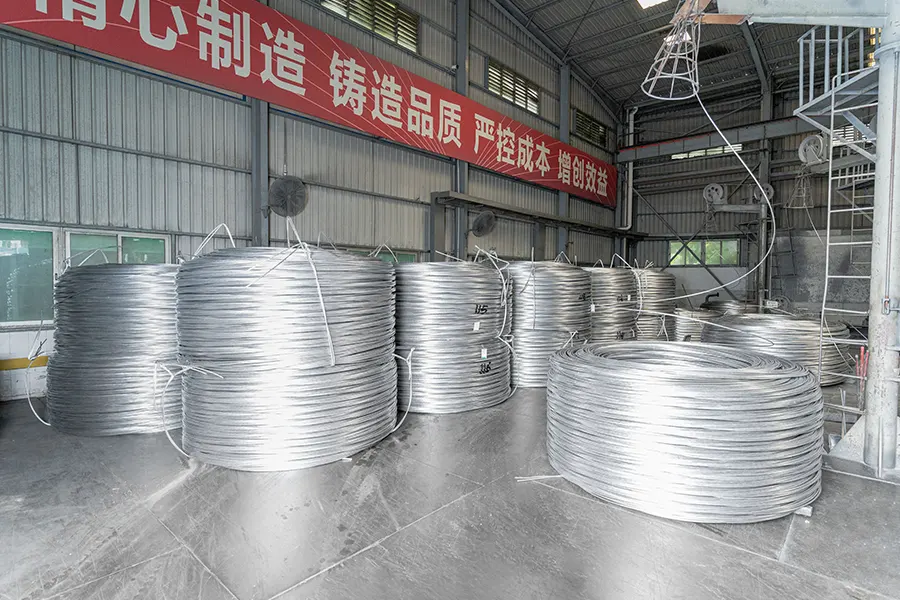

Quality Starts Here

Step 1: Raw Materials

We source premium raw materials, ensuring our cables meet strict industry standards from the very beginning.

Crafting the Perfect Conductor

Step 2: Wire Drawing

Our advanced wire drawing techniques reduce the diameter of metal rods, creating fine wires with superior conductivity and strength.

Building Strength and Flexibility

Step 3: Stranding

Individual wires are carefully stranded together to enhance the mechanical strength and flexibility of the final cable product.

Protecting the Core

Step 4: Insulation Extrusion

A layer of high-quality insulation is extruded onto the wires, ensuring durability and safety by preventing electrical leaks and protecting against environmental factors.

Shaping the Future of Power

Step 5: Cable Forming

Stranded and insulated wires are twisted or bundled together to form the final cable structure, tailored to meet specific application needs.

Additional Protection

Step 6: Inner Sheathing

An inner sheathing layer is applied to bind and protect the core components, enhancing the cable’s mechanical properties and resistance to environmental factors.

Strengthening for Tough Conditions

Step 7: Armoring

For cables requiring extra protection, an armoring layer is added, providing robust defense against mechanical damage and harsh environmental conditions.

Sealing for Safety and Durability

Step 8: Outer Sheathing

The final outer sheath is extruded onto the cable, offering a protective barrier that ensures long-term performance and reliability in various conditions.

Get in Touch with Us

Discover how LX CABLE can support your next PV project or other power transmission projects with our comprehensive range of products and services.